In various kinds of industrial machinery processing work fields, it is always getting different requirement of line length and line thickness in distance. In order to get quite accurate line targeting on various targeting surfaces, a lot of factory works are beginning to work with quite advanced laser diode tech applied red line laser alignment. The genuine laser line targeting work is different from any other type of manual line drawing or line printing work. When this green laser module is getting different line length and line thickness, it is just getting quite wonderful line targeting for all kinds of industrial and high tech line aligning works effectively.

When red line laser alignment is making use of a high quality and import 650nm red laser diode, the direct diode emission has just made workable for improving beam stability for long term line targeting work. In addition, among all available laser module device, 650nm wavelength made laser diode is getting the longest development history and mass production, which has just made it easily get stable and reliable enough line targeting in long term use. It is not only getting quite accurate red laser line targeting, but also available with quite low price. It is just being regarded as a quite nice line measuring tool workable for all kinds of industrial and high tech fields.

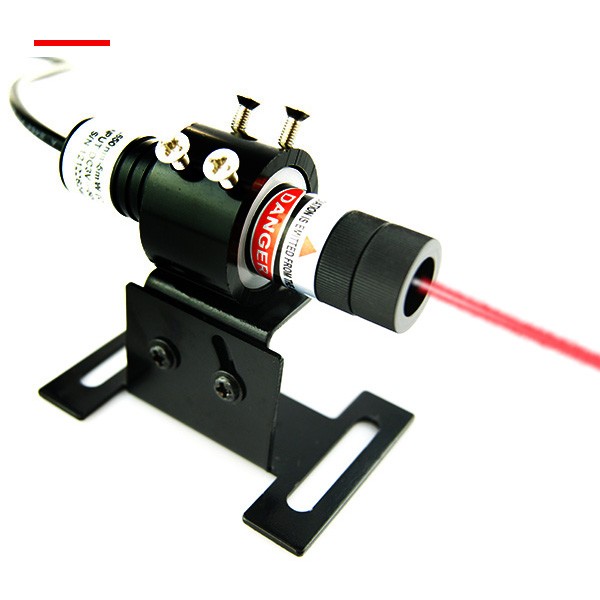

In order to get clear enough line targeting in various work fields, this red line laser alignment is always employing high quality glass coated lens or separate crystal lens. Whatever kind of targeting surface, it is showing clearly with a good linear quality red reference line. Red laser line is keeping high straightness and high fineness. Under condition that it is being used as an industrial applied laser line generator, it is getting strict tests of super rapid electric current adding test, alternative high and low temperature changing test and up to 24 hours aging preventing test, this alignment laser line is just keeping stable and reliable line targeting in long term use.

When line targeting is processed on different working surface, after enough learning of line length, line thickness and work distance from laser beam aperture to desired working surface, this red line laser alignment just gets free selection of otupt power and optic lens degree, and then getting high level of accuracy line targeting in long term use. When this alignment laser is being used with quite high power for long distance and high lighting, it is very important issue for users to wear proper laser safety goggles and avoid eye exposure at quite close distance, it will get wonderful line targeting marvelously.